Czech Researchers Developed Special Wrapping Paper for Electronic Devices and Explosives

16. August 2023A special type of paper which conducts electricity well and prevents undesirable effects of static electricity has been developed by Czech researchers thanks to the use of modified cellulose. The new material can be used for the packaging of electronic devices sensitive to static electric charge. More applications can be found, for example, in the packaging of explosive products, where static electricity could lead to an explosion. The project funded by the Technology Agency of the Czech Republic (TA CR) saw cooperation between researchers from the Centre of Polymer Systems of Tomas Bata University in Zlín and their colleagues from the Centre of Organic Chemistry and the Synpo company.

As part of the Green Deal initiative, the trend is to switch to renewable packaging materials that are not plastic-based and can be reused. All manufacturers are, therefore, trying to leave plastic packagings and replace them with more environmentally friendly options that do not require the extraction of mineral resources and their subsequent release into the environment, either directly or in the form of carbon dioxide after their combustion.

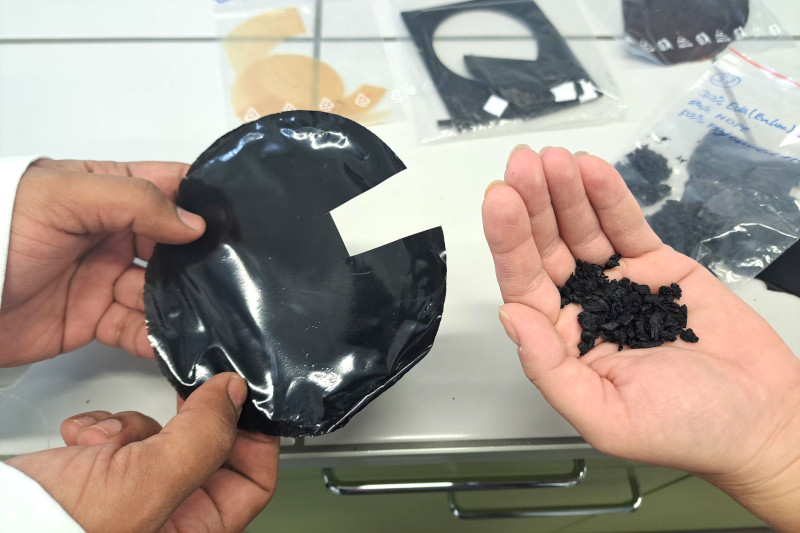

“Just for the packaging of electronic devices, the consumption of plastics is huge, and with the increasing percentage of online shops, their production, which pollutes the planet, is increasing. Therefore, any solution for switching to a different type of packaging is welcome and supported,” said Petr Konvalinka, Chairman of the Technology Agency of the Czech Republic (TA CR), which accepted the project for funding, providing almost CZK twelve million from the EPSILON Programme. In the field of packaging of sensitive electronic devices, explosives and other products that can be damaged by static discharges, it has not been possible to use paper packaging before without undesirable contamination of the paper substance. The paper substance must be supplemented with additives based on carbon fibres, graphite and the like, which are a foreign element in the paper.

“The new approach to the production of paper with antistatic properties is based on a direct modification of the paper pulp. Thanks to a patented process, a conductive polymer is inserted into the paper pulp. The resulting cellulose has, therefore, the required surface resistance and is, by using a standard procedure, blended into the paper substance. Any electric charge can, thus, easily be transferred to the final paper product even with a relatively low concentration of polymers,” explained Lubomír Kubáč from the Centre of Organic Chemistry, which has long been involved in innovative applications of conductive polymers.

In this manner, the paper acquires the ability of the so-called charge dissipation. This means that any electrical charge is completely diverted from the place where undesirable phenomena could occur. By using this new method, it is possible to prepare three types of paper, depending on the concentration of the polymer in the cellulose. The first one is conductive paper, preventing static charge. It can be used for common purposes when it is necessary to prevent the generation of static electricity, especially for packaging of products sensitive to static discharge. The second type of paper allows an efficient charge removal from the goods being packaged. It is designed primarily for packaging of electronic devices, explosive materials, detonators and the like. The third type of paper can be used as a substrate for flexible electronic devices or sensory systems. In addition to paper, the researchers, together with the Synpo company, prepared a primer coat containing conductive cellulose for concrete substrates for clean rooms. Modified conductive cellulose was also used in cooperation with the Centre of Polymer Systems at TBU in Zlín for the production of conductive plastics.

“Besides the development of special paper types, the project also included research into the possibilities of using modified cellulose fibres in order to improve the antistatic properties of polymer materials, which was actually our task. In this case, too, we have managed to develop a material with good antistatic properties, which can be used not only for packaging of electronic devices, but also for products intended for interior equipment of rooms, especially when there is a risk of explosion. Specifically, these are new types of floor coverings or paints,” said Prof. Vladimír Sedlařík, Director of the TBU Centre of Polymer Systems.